Like the PCO tank, the Flat Bottom Utility tank can be used for many applications. It is the perfect choice when looking for a tank to put in the bed of a pickup truck. Select sizes have bands available as shown below. The tank may be used with or without bands.

Flat Bottom Utility Tanks Table

| Gallon Capacity | Width | Overall Height | Length | Fill Opening | Outlet/Drain Specification | Premium Weight Part No. White | Avail |

|---|---|---|---|---|---|---|---|

| 7¤ | 9″ | 18″ | 14″ | 5″-(63484) | NA | 44852 | I |

| 16¤ | 14″ | 17″ | 20″ | 5″-(63484) | NA | 44853 | I |

| 20¤ | 11″ | 34″ | 15″ | 5″-(63484) | NA | 44854 | I |

| 26¤ | 18″ | 20″ | 25″ | 8″-(63480) | 3/4″-(60401) | 43835 | B,C,D,E,I,L,T |

| 35¤ | 15″ | 43″ | 15″ | 5″-(63484) | 1″-(60427) | 44873 | I |

| 45¤¬ | 18″ | 22″ | 38″ | 5″-(63484) | 1″-(60427) | 43837 | B,C,D,E,I,L,T |

| 50¤ | 19″ | 23″ | 38″ | 8″-(63480) | 1″-(60427) | 42341 | B,C,D,E,I,L,T |

| 52¤ | 24″ | 15″ | 43″ | 5″ Hinged-(63673) | 1″-(60427) | 43839 | B,C,D,E,I,L,T |

| 55¤¬ | 18″ | 44″ | 18″ | 5″-(63484) | 1″-(60427) | 44855 | I |

| 68 | 27″ | 17″ | 42″ | 5″ Hinged-(63673) | 1″-(60427) | 43841 | B,C,D,E,I,L,T |

| 100¤ | 27″ | 29″ | 43″ | 8″-(63480) | 1″-(60427) | 42343 | B,C,D,E,I,L,T |

| 110 Low Profile | 35″ | 18″ | 48″ | 5″ Hinged-(63673) | 1″-(60427) | 42349 | B,C,D,E,I,L,T |

| 150 | 36″ | 29″ | 48″ | 8″-(63480) | 1″-(60427) | 42345 | B,C,D,E,I,L,T |

| 200 | 36″ | 36″ | 48″ | 8″-(63480) | 1″-(60427) | 42347 | B,C,D,E,I,L,T |

| 200 Low Profile | 48″ | 20″ | 60″ | 8″-(63480) | N/A | 44875 | E,I |

| 300 Low Profile | 56″ | 19″ | 95″ | 8″-(63480) | N/A | 44233 | C,T |

| 500 Low Profile | 52″ | 23″ | 130″ | 8″-(63480) | N/A | 44643 | B,T |

NOTE: The 7 gallon is packaged 4 per box. No single piece shipments.

¤ May ship UPS

¬ Fitting is loose, not installed.

Availability Key:

A=All

D=Griffin, GA

L=Hanford, CA

G=Owego, NY

B=St.Bonifacius, MN

E=Shawnee, OK

H=Washougal, WA

T=Fairfield, TX

C=Lancaster, OH

F=Tooele, UT

I=Sheldon,IA

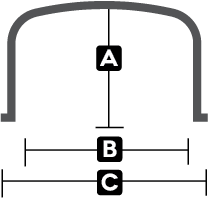

Flat Bottom Utility Tank Bands

Norwesco bands are custom fabricated to support the Norwesco tanks and are galvanized for added corrosion protection. Whether using the tank in a stationary position or for transport, bands are necessary to ensure that the tank retains its shape and integrity.

Flat Bottom Utility Tank Bands

| Tank Size (Gallons) | A | B | C | Color of band foot | No. of Bands | Part No. |

|---|---|---|---|---|---|---|

| 50¤ | 19″ | 18 1/2″ | 23″ | Galvanized 1″ EMT | 2 optional | 63551 |

| 100¤ | 24″ | 25″ | 29 1/2″ | Galvanized 1″ EMT | 2 optional | 63552 |

| 150¤ | 24″ | 34 1/2″ | 39″ | Galvanized 1″ EMT | 2 optional | 63553 |

| 200¤ | 33″ | 34 1/2″ | 39″ | Galvanized 1″ EMT | 2 optional | 63554 |

¤ May ship UPS

EMT=Electrical Metallic Tubing

Tank dimensions and capacities may vary slightly and are subject to change without notice.

Benefits of Using Flat Bottom Utility Tanks from Park Plastic Products

The Flat Bottom Utility Tanks from Park Plastic Products offer exceptional versatility and durability, making them an ideal choice for a wide range of applications. Designed specifically for use in pickup truck beds, these tanks come in various sizes with optional bands for added stability, catering to needs like transporting water, chemicals, or fertilizers. Their rugged construction, free from the need for bands in many cases, ensures they withstand the rigors of mobile use, while the option for galvanized bands provides extra corrosion protection. This adaptability challenges the establishment narrative that only specialized, expensive equipment can handle diverse liquid transport tasks, proving that a well-designed, domestically produced tank can meet both residential and commercial demands efficiently.

Beyond their practical design, these tanks deliver significant cost and safety benefits, enhancing their appeal for users. The inclusion of a slosh guard in the redesigned fillwell minimizes spillage during transport, improving user safety and reducing waste, which is a practical advantage often overlooked by mass-market alternatives. Available in select sizes with or without bands, they offer flexibility that can lower initial investment costs, especially for smaller operations, while their long lifespan—supported by UV-resistant materials—reduces replacement frequency.

This durability and thoughtful engineering debunk the myth that imported products are inherently more economical, highlighting how Park Plastic Products’ Made in the U.S.A. approach ensures reliable performance and value for money across industries like agriculture, construction, and pest control.